With dedication to Customer Service, we E-Coat a variety

of parts used in the Automotive industry in the United States.

ITSUWA is proud to be an industry leader in E-Coating of automotive components. With over 40 years of experience in Japan, we brought our success to the United States in 2009. Because we truly know the e-coating process in and out, we can provide high-quality cost-effective solutions to our customers from small to large quantities.

About ITSUWA

Itsuwa is an industry leader in the specialization of e-coating of automotive parts. With our roots starting in Japan in 1979, Itsuwa has grown to a 5 plant operation, 2 of which are here in the United States in Columbus, IN and Bardstown, KY.

Itsuwa will provide quality products to our customers with total customer satisfaction while promoting continual improvement utilizing quality management systems. Itsuwa will establish leadership in the market place with superior E-coated products.

We strive to provide total customer satisfaction through promoting continual improvement. We accomplish this through our guiding principles. We are committed to anticipating, understanding and meeting our customers’ needs and expectations. We strive for constant innovation for our long term success. We believe in solid leadership and commitment to our customers. As a family company, we believe in the value of enduring personal relationships with customers, suppliers, and industrial partners.

“Quality at ITSUWA is, and will

continue to be, our first priority”

– President Hisashi Ando

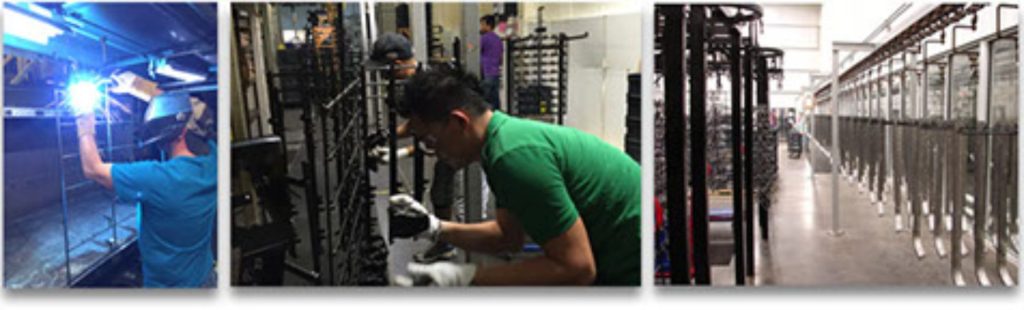

ITSUWA team

What can we do in 2 hours?

Cathodic Electrocoating (E-coat)

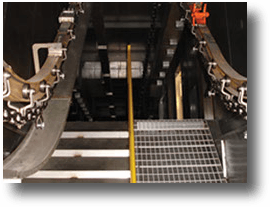

1. PARTS LOADING

Our quick handed loaders are the first step to get all the parts prepared and loaded onto a conveyer.

2. PRETREATMENT

Parts head up the line for an important pretreatment. Dip and spray cleaning stages remove any unwanted dust or debris particles, followed by our Zinc Phosphate System to prepare the surface for E-coating.

3. E-COAT BATH

Our water based cathodic electrocoating bath is next. Within the bath, electro fields create an atmosphere for the pigment to adhere to the metal component and creates a film on the material surface.

4. POST RINSES

Post rinse stages remove any excess paint pigments on the surface.

5. CURING

We offer low temperature curing process to laminate the film for the maximum performance.

6. UNLOADING/INSPECTION

Components get unloaded from the conveyor and go through inspection process to assure Quality of E-Coat.

Before E-coat

After E-coat

CAPABILITIES

LOAD SIZE:

Various load sizes from small stamping products to the maximum load size of L 50” x W 30” x D 16”

(L 1,270mm x W 760mm x D 405mm).

MATERIAL:

Steel, galvanized steel, stainless steel and other metal components

AIRBLOW:

Airblow process between the main paint tank and the cure oven minimizes water / drip marks on the products.

TOOLING:

In-house fabrication of hanger racks to any necessary tools give us the maximum flexibilities and minimum turnaround time.

QUALIFIED STANDARD SPECIFICATIONS

TIS 01206-00050, TIS 01206-00344, TSH 2354G, TSH 3600G, TSH 2106G, TS 430-7-89, DBL 7381, etc.

Our QUALITY POLICY:

ITSUWA will provide quality products to our customers with total customer satisfaction while promoting continual improvement utilizing quality management systems. ITSUWA will establish leadership in the market place with superior E-Coated products.

Contact ITSUWA

Indiana Plant

Itsuwa USA, LLC

1349 Arcadia Drive

Columbus, IN 47201

Ph: (812)375-0323

Fax: (812)375-0383

Japan Plant

Itsuwa Seisakusho Co., Ltd.

13 Nagane, Kanpachi-cho,

Toyota-shi, Aichi 470-0328, Japan

+81-565-41-2201

itsuwa-ss.co.jp

Kentucky Plant

Itsuwa KY, LLC

659 Wilson Parkway Bardstown, KY 40004

Ph: (502)349-2091

Fax: (502)348-3556